The JW Series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an aggressive crushing stroke to maximize productivity. The accompanying table gives

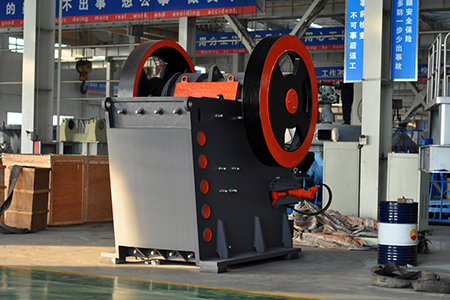

Single Toggle Jaw Crushers Typical applications for our single-toggle jaw crushers are in mining, quarrying and recycling. The jaw crushers handle ores, rock, gravel and recycled concrete.

Terex Jaques Jaw Crusher ST-Series-JawBrochure - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world's largest social reading and publishing site.

The Cedarapids® CRJ3255 plant combines the popular JW55 jaw crusher with a high stroke, 52” x 20’ (1321 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing

Discover the powerful performance of Jaw Crushers, engineered for durability and precision in material processing. Designed to handle a variety of applications, our Jaw Crushers offer a

The J50’s jaw speed leads to better reduction and material being processed faster through the crushing chamber. McCloskey International has a proven reputation for designing quality, best

Terex® JW Series Jaws. Rugged, Dependable, Productive. Terex ® Minerals Processing Systems jaw crushers are known for durable construction, high productivity and a

Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable. The movable jaw plate approaches the fixed jaw plate periodically to realize the

The Terex ® Jaques Single Toggle jaw crushers feature large gape feed openings, The jaw crushers handle ores, rock, gravel and recycled concrete. Products;

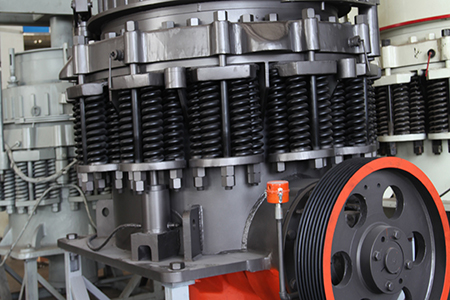

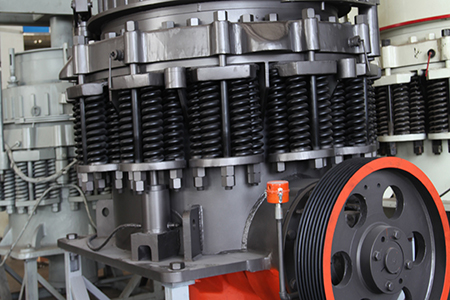

Although the jaw size is specified by the dimensions of the top rectangular opening, jaw length is also very important determining the performance and production capacity of the crusher. The jaw components, namely: nut screws, ball screws, jaw fitting screws and cane bolts are all manufactured from hardened steel, which extends the durability of parts in heavy duty

Introduction to Jaw Crusher Equipment. Jaw crushers are a type of rock crusher that uses a fixed jaw and a moving jaw to crush materials.The fixed jaw is stationary and acts as a support for the moving jaw, which pivots on an eccentric shaft. This motion causes the crushing chamber to open and close, crushing the material between the two jaws.

Designed around our proven, high-performance Cedarapids® JW55 jaw crusher, the MJ55 Modular Jaw Crusher is designed for large quarries or contractors that want a stationary type design without the complexity of... Learn More about

Explore Australia's largest excavators, loaders and trucks site Jaques Screening - Crushing for sale

The heavy-duty, general-purpose JC3000 Jaw Crusher is a well-proven, highly productive primary crusher used in sample preparation and plant applications. More powerful than the JC2000, it is suitable for higher workloads and can handle large core and lump crushing.

Jaw crushers are widely used in the crushing of various ores and bulk materials in industries such as mining and smelting, building materials, highways, railways, water conservancy and chemical industry. Details . 10 2024-09. How to improve the quality of basalt sand making?

Jaw Crushers The JW Series is engineered for portability and ease of use. The rugged design delivers the reliability you can expect from Cedarapids. They feature a hydraulically actuated wedge system that allows variable closed side-setting adjustments to be made quickly and easily.

Order Information-Jaw Crusher JC5: Item No. Description: 24.871.0007: Jaw Crusher JC5,380V, 50Hz,Please order jaw plate and side liner separately Jaw plate and side liner should be ordered in pair: 11.871.1048: Jaw plate, manganese steel(precision casting), 1 piece 11.871.1049: Jaw plate, stainless steel, 1piece 11.871.1050

The jaw crushers handle ores, rock, gravel and recycled concrete. Proven design with a long history of trouble free operation in tough mining and quarrying applications; Frame fabricated from low carbon steel, reinforced with ribs throughout.

Jaw Crusher Disadvantages: Maintenance Intensive: Although maintenance is simple, it needs to be frequent to ensure optimal performance, especially for heavy-duty usage. Abrasive Material Wear: Jaw crushers can experience excessive wear on their metal surfaces when processing abrasive materials, impacting their longevity.

2024年4月6日 History of Jaw Crushers. Jaw crushers have a rich history that dates back to the 19th century. They have evolved over the years, with key innovations in their design leading to improved efficiency and performance.

Mobile jaw crushers The crushing plants in the MOBICAT series are used for pre-crushing of almost all natural stone and for recycling. The output of the MOBICAT crushing plants, however, is not determined by the jaw crusher

The Terex Finlay J-1175 is a high performance and aggressive tracked mobile jaw crusher. Incorporating a Terex Jaques JW42 jaw crusher and a heavy duty vibrating grizzly feeder the Terex® Finlay J-1175 gives optimum production in

Jacques gyratory cone crusher sale Australia – Stone Crushers. PE Series Jaw Crusher; PEW Series Jaw Crusher; Jacques Gyratory Cone Crushers are of robust design with built-in safety system for non-crushable materials and are

Subscribe To Newsletter. and receive new ads in inbox. Subscribe. Quick Links

Dodge Jaw Crusher: Similar to the Blake crusher, the Dodge crusher has a movable jaw that moves towards and away from the stationary jaw, and is preferred for crushing softer particles. Universal Jaw Crusher: This type has a “V”-aligned fixed jaw and a movable jaw on an eccentric shaft, creating an elliptical motion.

Jaw Crushers The JW Series is engineered for portability and ease of use. The rugged design delivers the reliability you can expect from Cedarapids. They feature a hydraulically actuated wedge system that allows variable closed side-setting adjustments to be made quickly and easily.

890mm (35″) wide x 500mm (20″) Jaw Crusher. N. 218Hp (162kW) Volvo D5 T3 or T4 Final engine. N. Integrated hydraulic folding stockpiling conveyors. N. I-beam plate fabricated chassis construction. N. Open chassis design for ease of maintenance. N. Crawler Tracks with the ability to track and crush simultaneously. N. Fast setup time.

Jaw Crusher Disadvantages: Maintenance Intensive: Although maintenance is simple, it needs to be frequent to ensure optimal performance, especially for heavy-duty usage. Abrasive Material Wear: Jaw crushers can experience excessive wear on their metal surfaces when processing abrasive materials, impacting their longevity.

The jaw crushers handle ores, rock, gravel and recycled concrete. Proven design with a long history of trouble free operation in tough mining and quarrying applications; Frame fabricated from low carbon steel, reinforced with ribs throughout.

حقوق الطبع والنشر: شركة خنان ليمينغ لتكنولوجيا الصناعة الثقيلة المحدودة. رخصة أعمال